It appears like a penny. Welding 6mm mild steel Fillet joint 18-20V 120a TriMix shielding gas Wire feed to a good sizzle Any suggestions will help.

Mig Welding Basics Part 6 Vertical Uphill Tee Joint Drill

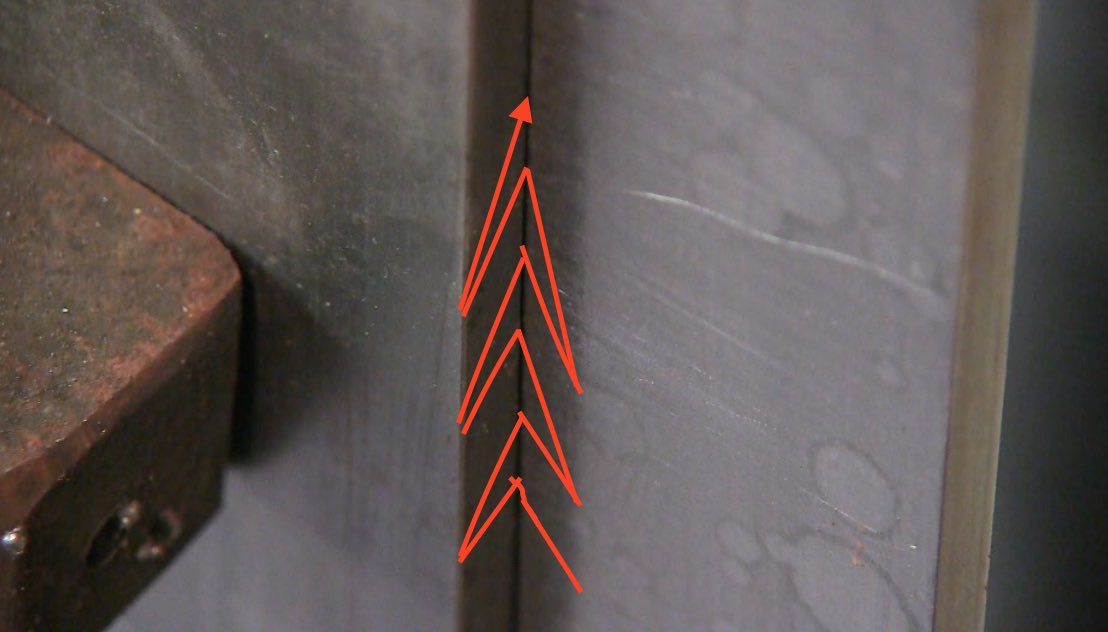

MIG welding in the vertical up position produces a very convex weld.

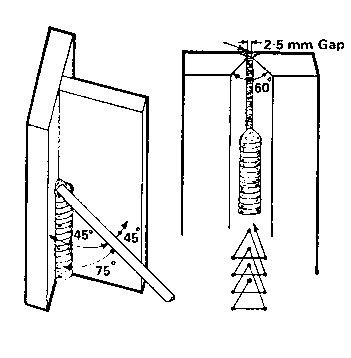

. Vertical Up MIG Welding Techniques. The MIG gun handle should be pointed up between 35 to 45 degrees. This is popular with flat horizontal and overhead stick welding.

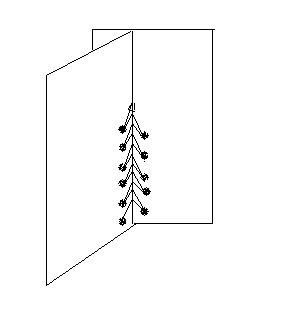

Working uphill the welder can use a variety of patterns to spread the filler metal into the joint. This pattern greats a flat stack of dimes. Forehand vs Back-Hand.

When it comes to the MIG welding position one of the most difficult techniques is the vertical up position as you need to have the MIG gun pointed upwards at an angle of 35-45 degrees. During a vertical up MIG weld using the inverted v pattern my weld bead has a droopy apearance. If your having to weld vertical up with mig and your welding anything thicker then 14 material run a dual shield wire e71t and not only will the weld appearance be much bettar but you can easily weld vertical up and not have the puddle fall out.

So if you want to practice its best to start at 45. Use the right wire. Vertical up is the most difficult of the MIG welding positions.

The figure eight and zigzag weaving motion is a good technique for making a cover pass when you are in the vertical welding position of flat welding position. MIG welding is one of the most popular welding methods in use today primarily because of its ease of use and its ability to weld continuously using a spool of wire which is fed through the MIG gun as a short consumable electrode which basically The post Tips for MIG Welding Vertical Up appeared first on Weld My World. Also remove valuable equipment or cover it with welding blankets.

When you should not weave for MIG welding you have three other options. Whipping is distinctly different from weaving and the circle pattern technique is a combination of the two. The best welders are quite fussy about surface preparation and cleaning the base metal is a good habit to get into.

A vertical weld can be performed in. Upside Down V MIG Welding The key to the upside down V uphill MIG welding technique is tracing the edge of the puddle. Vertical welding needs concentration and stability.

Thus you will need to take certain considerations such as a reduction in amperage of your machine at first because the hotter the puddle the more easily it will drop to the ground. The molten metal seems runny. It is very difficult to make a flat or concave weld in the vertical up position unless the weld is wide.

In other words you gradually weld uphill by moving your arc to the front of the puddle tracing it back and forth uphill in a steady V motion. Runny weld bead Nick Walkley Member. The main difference is that the electrodes have a hollow center filled with fluxThe flux is what shields the weld area from the air and is the main reason this process works better outdoors.

MIG welding is more tolerant of minor surface contaminants than TIG welding but the cleaner the metal the fewer problems youll have. The chart below includes all 8 techniques above plus two more the V and the upside down V which can be used uphill. The upside down V is one of the most effective techniques for vertical mig welding of lap and tee fillet welds.

If I have an L shaped area to weld with one of the two sides being vertical I will run a J type pattern ware I creat a ramp with each stroke to run up and hold it aginst the vertical piece. Vertical down is a different story and produces a flat to concave weld. Vertical Up MIG Welding Technique.

Sure there are other ways of making a good looking vertical uphill weld but for ensuring penetration as well as making a good looking uniform weld the upside down V is a very good way to go. Steady Motion Whipping Circles Weaves Steady Motion This is the most basic technique used in MIG welding which is commonly used by robots where welding is done is highly professional and perfect in the output produced. Those options are comprised of the circle holding still and whipping.

This pattern makes a nice contour to the weld with the end result looking like butterfly wings. If you need help with welding vertical up it always a. Ensure you dont have any equipment nearby because welding spatter can damage or permanently scar most surfaces.

The vertical up weld in MIG is typically very convex. For thin metal where burn-through is a concern direct the wire away from the weld puddle. 05-02-2012 0458 PM.

The electrodes or filler wire used in FCAW is completely different then MIG welding. If you insist on running hard wire on vertical up then. It creates a reef-like bead drooping to the ground.

Vertical 7018 welding can benefit from using a weave type pattern. Because vertical down welding helps avoid excessive melt-through welders sometimes place very thin materials in the vertical position even if they can weld them in the flat position. MIG was the only process we didnt do vertical in maybe for good reason but we did vertical OFW SMAW and TIG.

I welded up some new spring and shackle perches on our 49 Jeep Willys frame yesterday and I knew from welding school that welding vertical was going to be different we didnt do vertical MIG welding at schoo. In stick welding beads we can also go for some cellulose stick rods. 10 Techniques To Practice.

And during vertical up GMAW welding the welder needs to create a weld shield to move upwards. When welding vertical up you need to build a shelf of weld to work upward on. Flux Cored Arc Welding Electrodes.

Weaves are much easier on vertical tests but sometimes CWIs will only allow stringer passes. Like weaving there is a separate forehand and backhand method for each pattern. Vertical welding position requires you to work against the force of gravity.

Thus the welder can use many different patterns to spread the filler material on the alloy surfaces. Vertical welding is easier when the base metal is at 45 and harder at 90. Weave type pattern is preferred in vertical welding.

The trick to welding downhill is to stay ahead of the puddle and weave quickly. Vertical MIG welding is one of the most difficult and tiring welding position to master. When welding vertical down begin at the top of a joint and weld down.

These must be used with proper technique. The commonly used welding patterns are. MIG welding doesnt produce much spatter but for vertical welds its best to wear long leather sleeves or a robust welding jacket and a fire-resistant cap.

Best Mig Welding Techniques For Everyone

Smaw Weave Patterns Google Zoeken Soldadura Mig Proceso De Soldadura Proyectos De Soldadura

Welding Vertically Mig Welding Forum

This Vertical Mig Welding Technique Will Penetrate

Vertical Uphill Welding Technique

Vertical Up Settings Help Mig Welding Forum

0 comments

Post a Comment